Threaded constant flow valves

How do our threaded constant flow valves work?

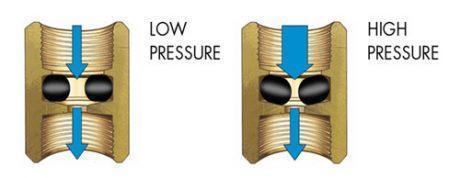

BT-Maric threaded constant flow valves utilize a flexible rubber control O-ring, with an orifice diameter that responds instantly to pressure variations (within a given range).

When the pressure increases, the O-ring is pressed down into the conical seat and the orifice of the O-ring decreases in size so that the flow remains constant at the pre-determined nominal rate, and vice-versa.

In this way, the pre-determined nominal flow rate is kept constant regardless of the pressure variations.

BT-Maric threaded constant flow valves

BT-Maric constant flow valves provide a constant, pre-determined, nominal flow rate for water and similar media regardless of the pressure variations. BT-Maric constant flow valves are designed for pipes from 1/8″ up to 2″ and regulate flow rate from as low as 0,15 L/min up to 342 L/min.

Unique Features :

- Wide range of flow rates available for water and other media as low as 0,15 L/min up to 342 L/min.

- Wide range of sizes ⅛″, ¼″, ⅜″, ½″, ¾″, 1″, 1¼″, 1½″, 2″ or higher if needed and threaded connections (FF, FM, MF, MM).

- Simple, compact, reliable and characterized by a long life (up to 20 years).

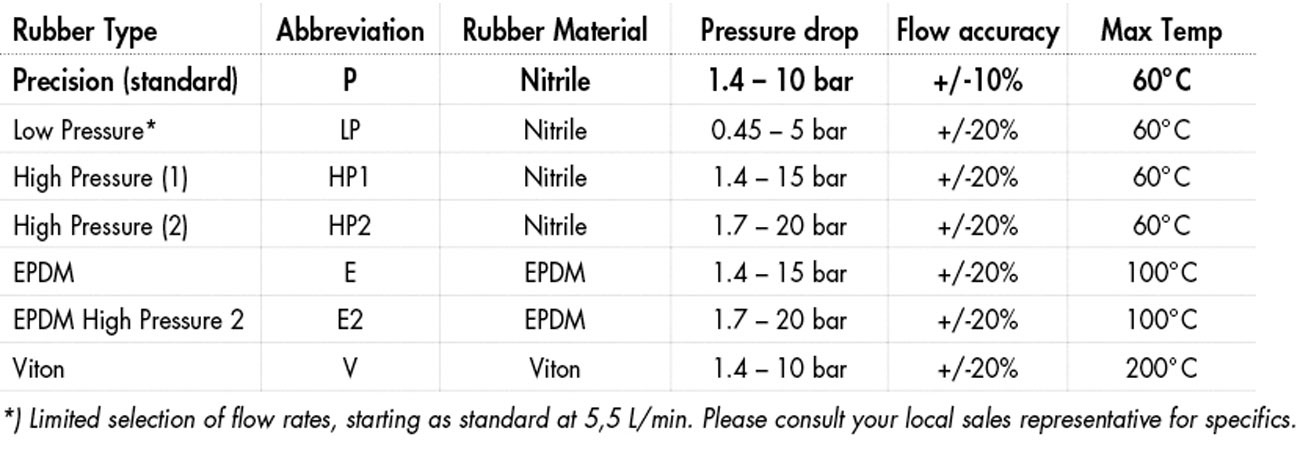

- High accuracy of flow control: With our standard control rubber types PRECISION, we achieve an accuracy level of +/- 10% of the nominal flow rate. PRECISION covers the pressure drop range of 1,4-10 bar. (Other pressure drop ranges are available).

Click to view all features

• Solutions available from 0,4 bar up to 20 bar.

• A wide variety of materials available: brass, stainless steel, gunmetal, U-PVC, POM, PVD-F, Titanium, Duplex, PE …

• 100% mechanical solution: no additional power source needed.

• Self-cleaning, self-regulating.

• Maintenance free: no need for spare parts. Due to the valves unique design and lack of wearing components spare parts are not available.

• The constant flow valves are primarily for water applications and these valves are particularly suitable for use on poor water quality, because the flow controlling element is a rubber material, and flexes under normal operation conditions. This greatly minimizes the risk of blockage and eliminates the build-up of scale.

• Pre-set flow rate to avoid adjustment errors or unwanted system changes.

• Customized solutions are available.

Download Data Sheets :

Brass Threaded valves

U-PVC Threaded valves

316 Stainless Steel Threaded valves

View all Data Sheets

Flow Control Check Valves – 15mm

Flow Control Check Valves – 25 mm

Installation instructions

How to specify your constant flow valve

Read more about our range of constant flow valves, type inserts and wafers.

Specifications for BT-Maric standard threaded constant flow valves:

![]() Standard nominal flow rate 0,15 – 342 L/min depending on valve size.

Standard nominal flow rate 0,15 – 342 L/min depending on valve size.

![]() Standard flow rate accuracy: +/- 10% within the pressure drop range of 1,4 – 10 bar.

Standard flow rate accuracy: +/- 10% within the pressure drop range of 1,4 – 10 bar.

![]() Standard operating pressure drop range: 1,4 – 10 bar.

Standard operating pressure drop range: 1,4 – 10 bar.

![]() Standard Operating Temperature:

Standard Operating Temperature:

≤ 60°C

![]() Connection size from ⅛″ up to 2″: ⅛″, ¼″, ⅜″, ½″, ¾″, 1″, 1¼″, 1½″, 2″ (Standard ISO 228/1 BSP).

Connection size from ⅛″ up to 2″: ⅛″, ¼″, ⅜″, ½″, ¾″, 1″, 1¼″, 1½″, 2″ (Standard ISO 228/1 BSP).

Other connection sizes

NPT threads are available in F/F ⅛″, ¼″, ⅜″, ½″, ¾″, 1″, 1¼″, 1½″, 2″ in Stainless Steel only

Female/Female

![]()

Standard materials for valve body: Brass, U-PVC and Stainless Steel

Other material options

Examples: POM, PVD-F, Titanium, Duplex, PE …

![]() Do not hesitate to contact us for any queries. We will be more than happy to provide you with either a standard or customized solution.

Do not hesitate to contact us for any queries. We will be more than happy to provide you with either a standard or customized solution.