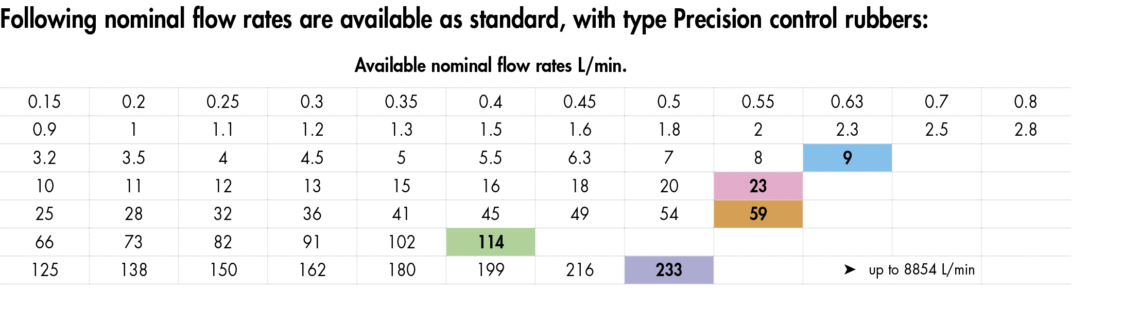

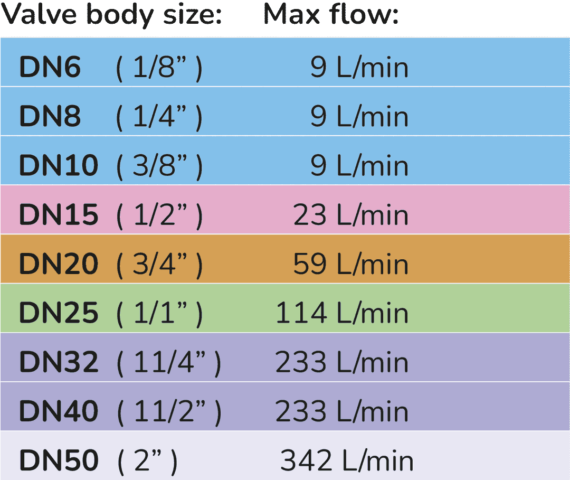

How to specify our BT-Maric constant flow valve?

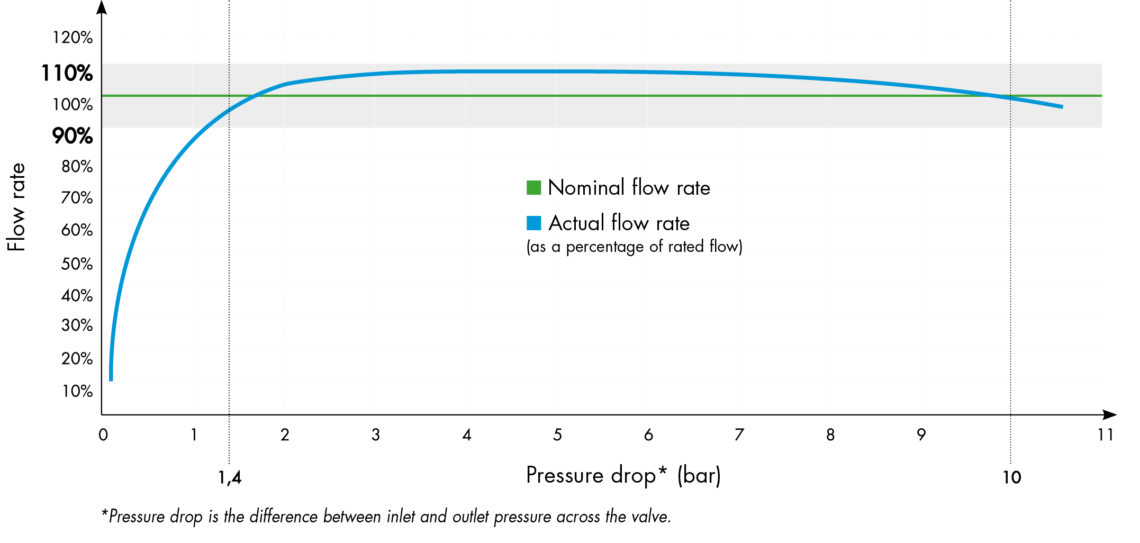

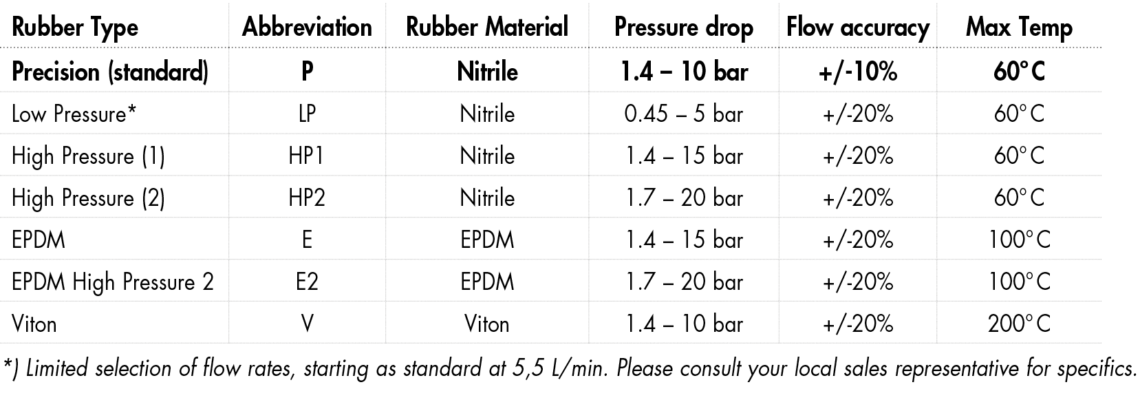

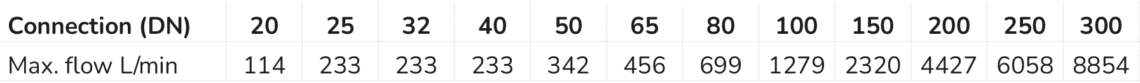

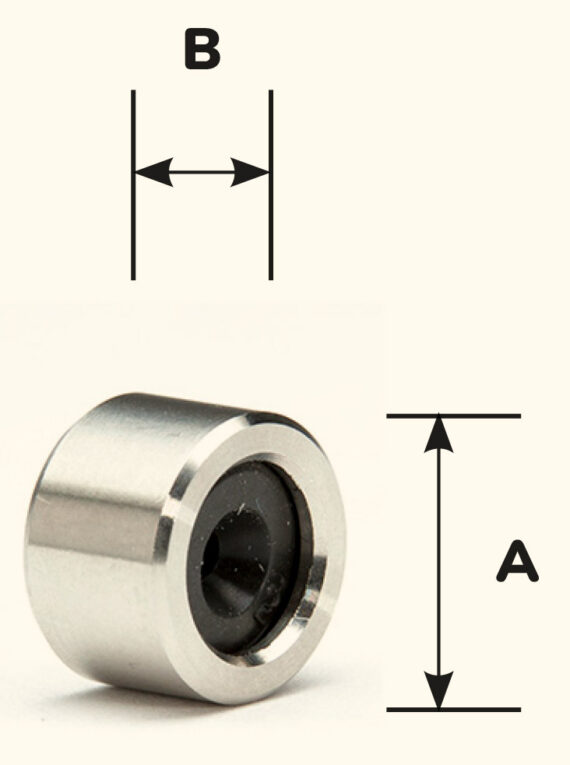

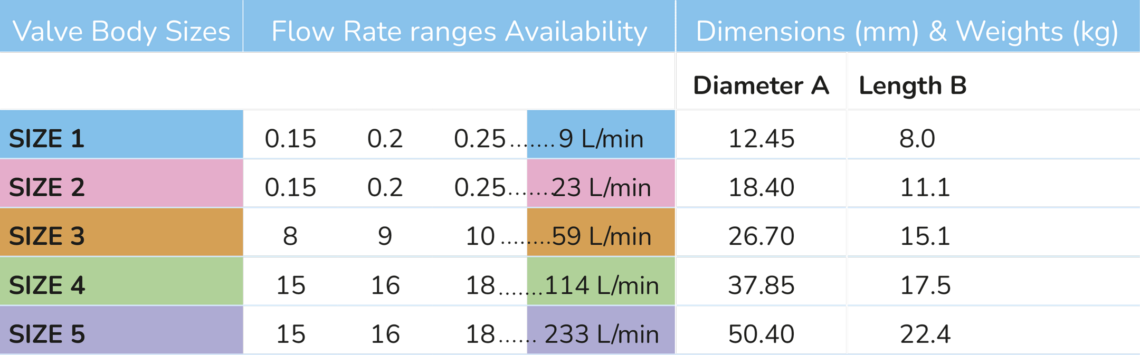

BT-Maric Flow Control Valves maintain a fixed, pre-set, constant flow rate, regardless of pressure. BT-Maric Constant Flow Valves are engineered to provide precise, reliable flow rates, ensuring optimal performance in a variety of applications.