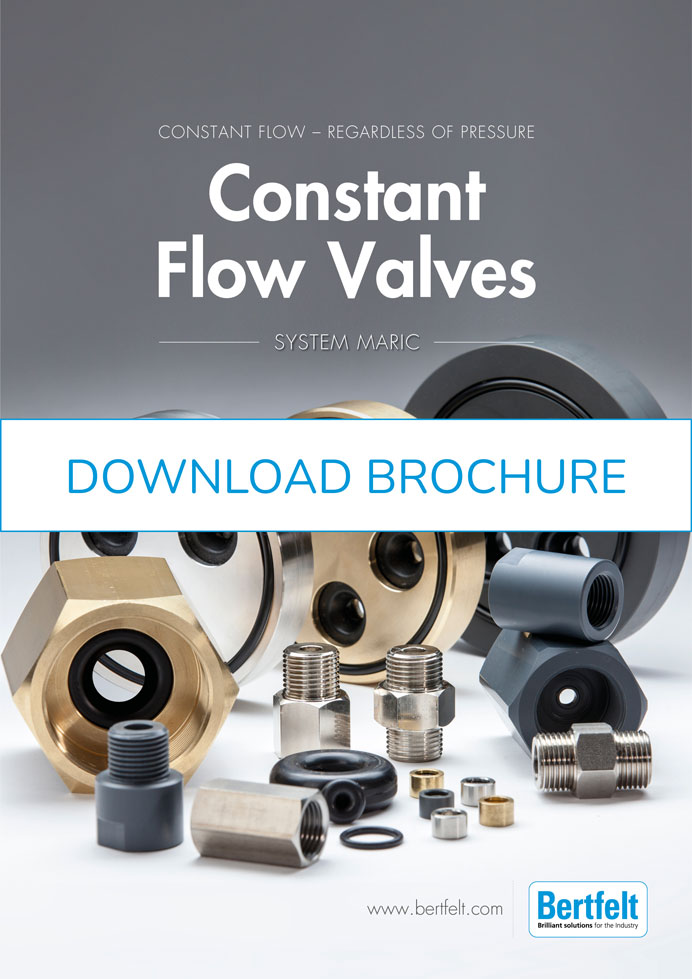

BT-Maric Constant Flow Valves save water and make products and processes more efficient – by always providing the chosen specified flow rate. The many unique features make the valves suitable for a variety of applications.

Standard connections

The BT-Maric Constant Flow Valves are available

in 3 standard connections:

Threaded constant

flow valves

BT-Maric Threaded Constant Flow Valves are designed for pipes from 1/8″ up to 2″ and regulate flow rate from as low as 0,15 L/min up to 342 L/min.

Constant flow valve

type Inserts

BT-Maric Inserts are designed to be fitted inside existing pipe work or other equipments. They control flow rates up to 233 L/min.

Constant flow valve

type Wafers

BT-Maric Wafers are designed to be placed between flange for pipe sizes between DN20 up to DN400. They control flow rates up to 13.500 L/min.

Any questions?

Contact us today for more information about our standard or Tailor-made OEM solution.

Many applications, one solution

BT-Maric Constant Flow Regulators are designed to your flow rate specification and deliver a pre-set (non-adjustable) flow rate, that automatically controls the flow of fluid in a pipe – irrespective of varying pressure differential.

The most common applications are:

industrial

- Dosage systems – usually together with a magnetic valve for easy control of fluid mixing.

- Industrial (washing) processes – precise control of chemical mixtures.

- Mechanical seals – constant flow valves are used to regulate fluid flows to pump gaskets and to regulate water flows in bore holes.

- Cooling systems – ensure the correct amount of fluid in the system.

water treatment

- Watertreatment & filtration equipment – creates optimum return flows to prevent damaging sensitive filters.

water autorities

- Municipal waterworks & water authorities

– limits maximum water tapping to allow better dimensioning of systems.

– improve efficiency and reduce waste.

irrigation and farming

- Watering installations in irrigation and farming projects – ensure optimum fluid flow at all outlet points.

- Animal farms – correct and limited flow to all animal stalls.

project market

- District heating distribution – creates optimum return flows to ensure minimum flow during summer period.

- Commercial facilities – hotels, restaurants, condominiums, event area.

– shower, sinks, toilets, drinking fountains; reducing excessive water usage. - Humidifiers – ensure the correct fluid flow in the system.

pump protection

- Mining and wellpoint installation – gland water flow control to gland-packing/stuffing box and mechanical seals of centrifugal and slurry pumps.

- Machines and plants

– ensure that an operator cannot wrongly adjust the fluid flow by mistake.

– ensure the correct amount of fluid to machines in export countries where water pressures could vary.

Fetch facts

Learn more

Hans Bodin, Managing Director of Åkab System, has been using BT-Maric Constant Flow Valves for many years in process equipment for the Swedish Food Industry.

Mr Bodin says that “In all projects we make sure to streamline and find resource-saving solutions when it comes to water and energy. In many of these projects, Constant Flow Valves are used to limit water consumption”.

Hans Bodin / Åkab System.