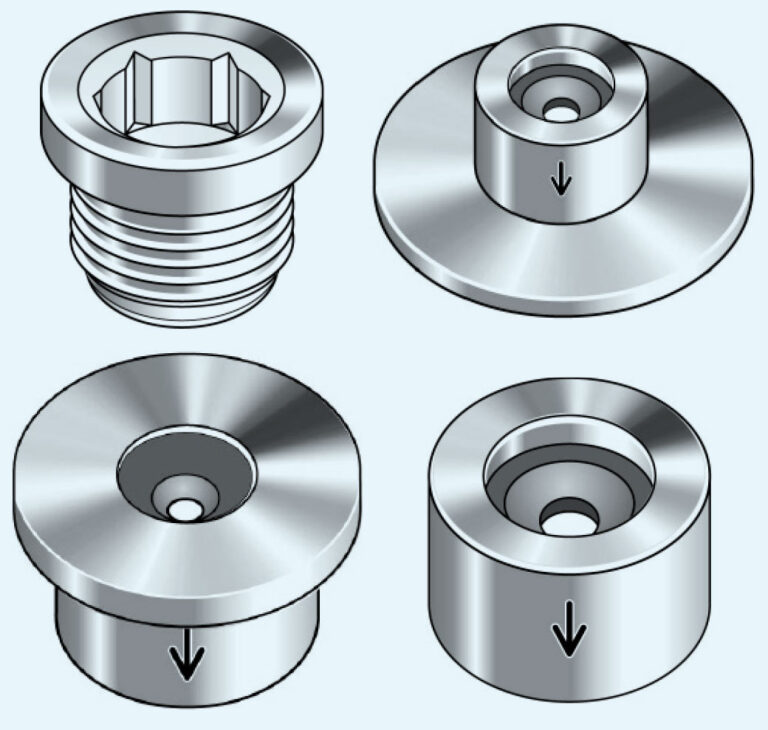

BT-Maric Constant Flow Valves – Insert Type

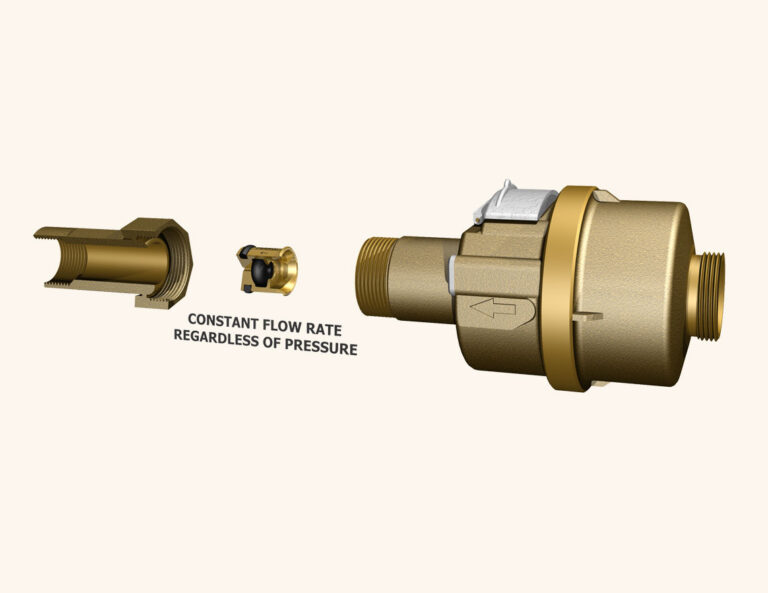

BT-Maric constant flow valves of the Insert type are compact, cost-effective flow control components designed for easy integration into OEM equipment and high-volume production systems. They are intended to be press- or slip-fitted directly into existing housings or pipework.

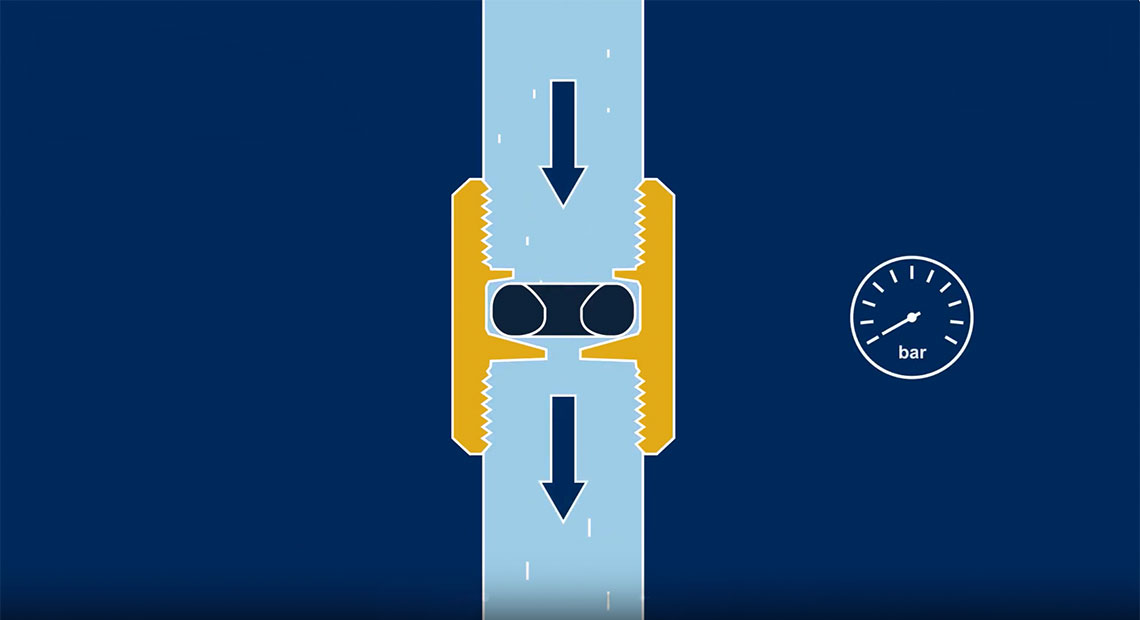

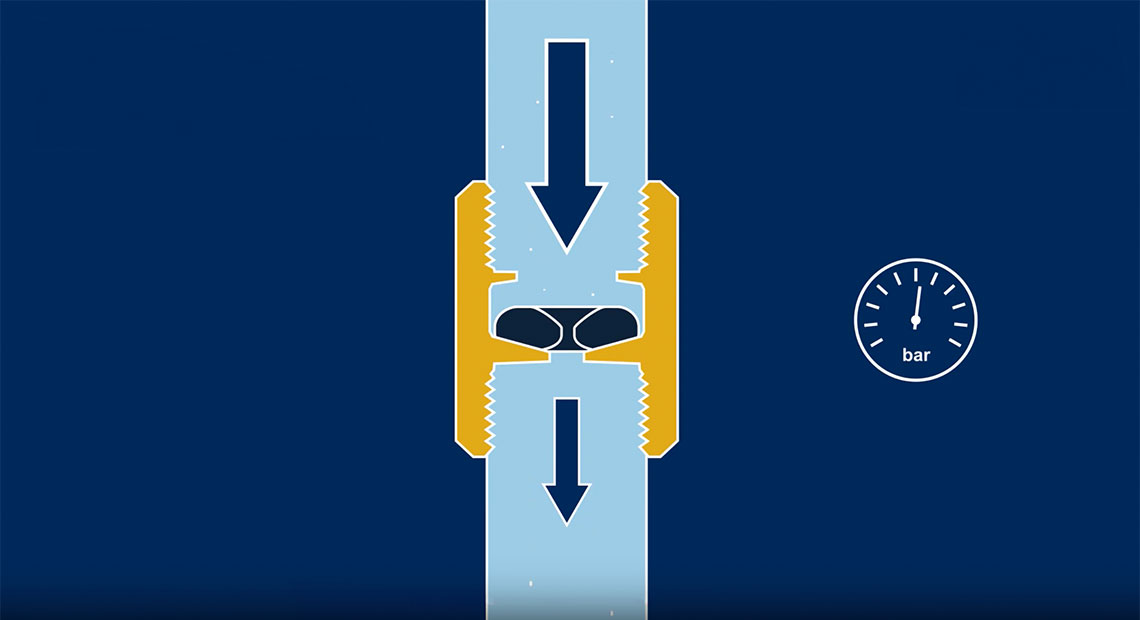

These inserts deliver a constant, pre-set flow rate for water and similar media, regardless of fluctuations in system pressure. This makes them an ideal solution for manufacturers seeking to ensure flow stability in compact designs without the need for external regulation or adjustment.