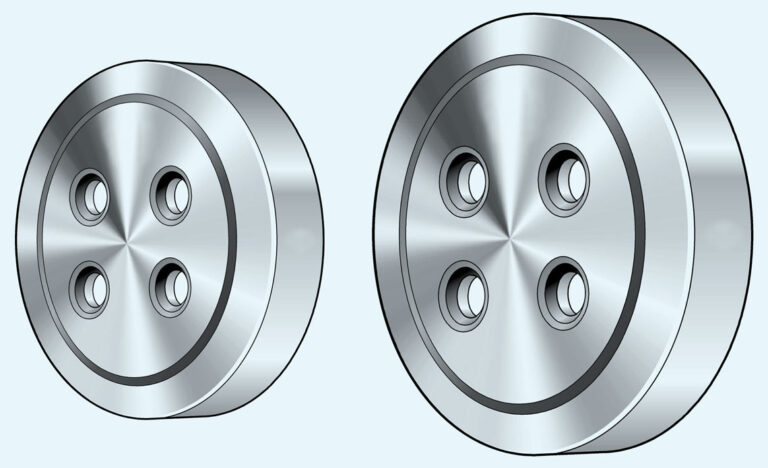

BT-Maric constant flow valve type Wafers

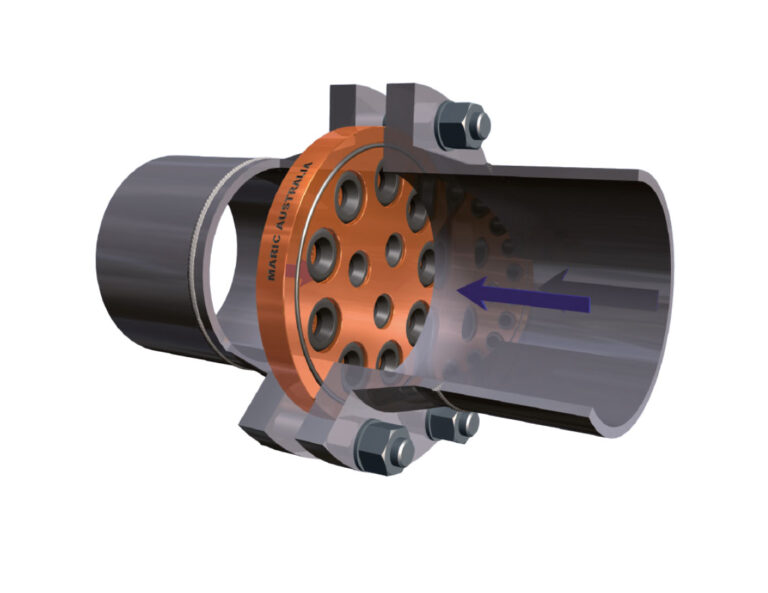

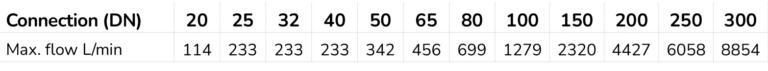

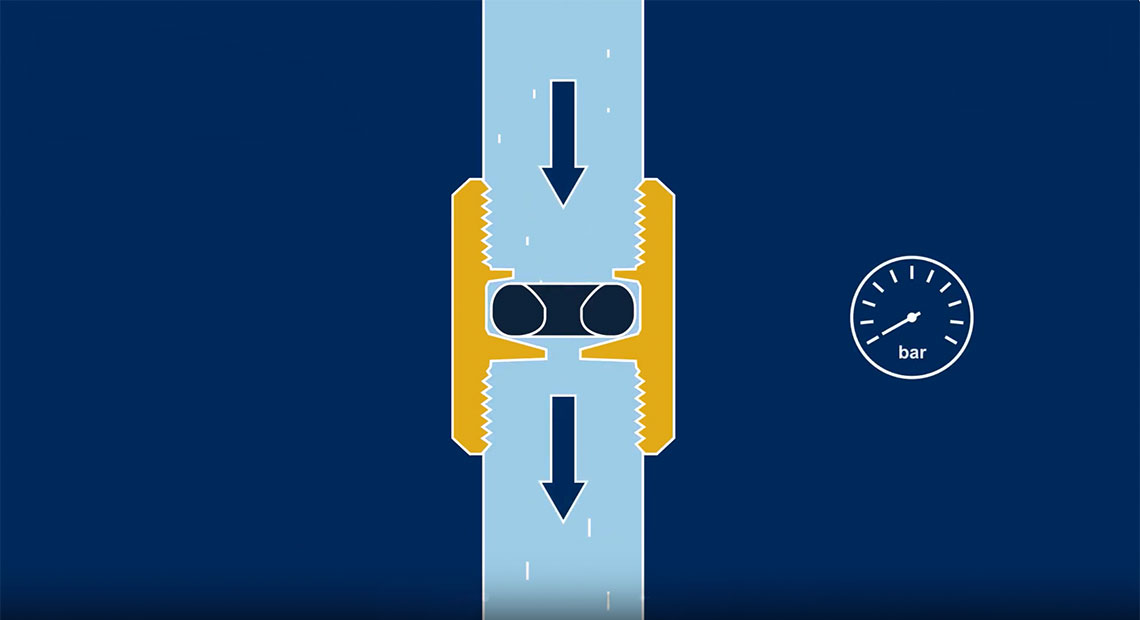

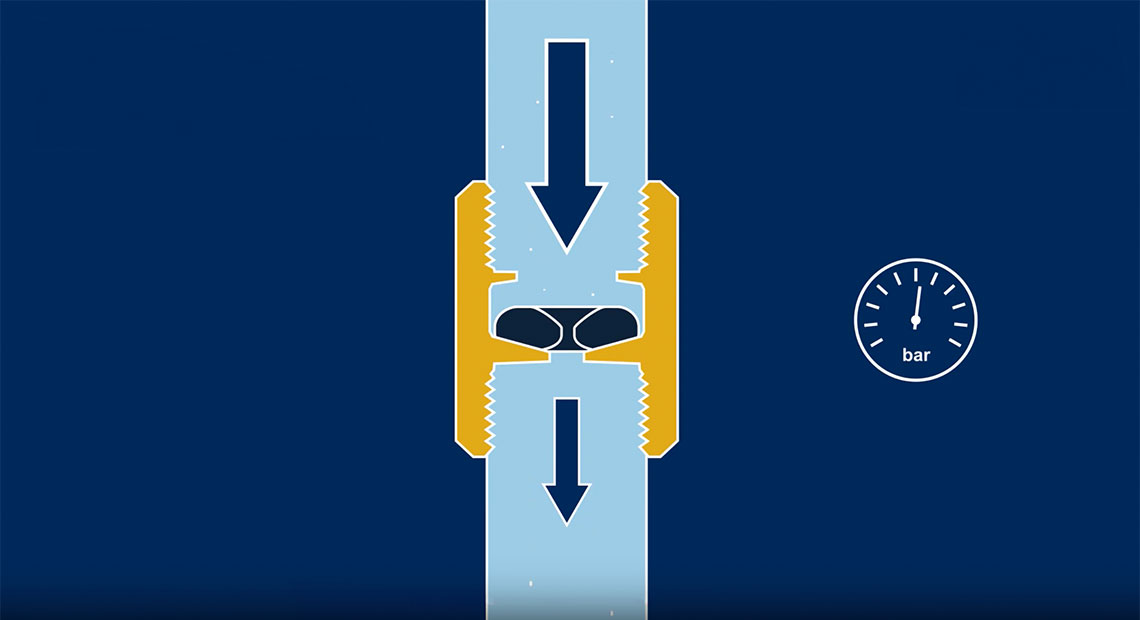

BT-Maric Wafers provide a constant, pre-determined, flow rate for water and similar media regardless of the pressure variations. Wafers are very compact and designed to fit between pipe flanges. They are available to suit a wide range of flange specifications. The standard Wafer is ISO PN10 but numerous specifications and standards are available including ANSI, DIN Standard etc. Wafers are the prefered choice for larger size valves and larger flow rates.