BT-Maric flow limiter

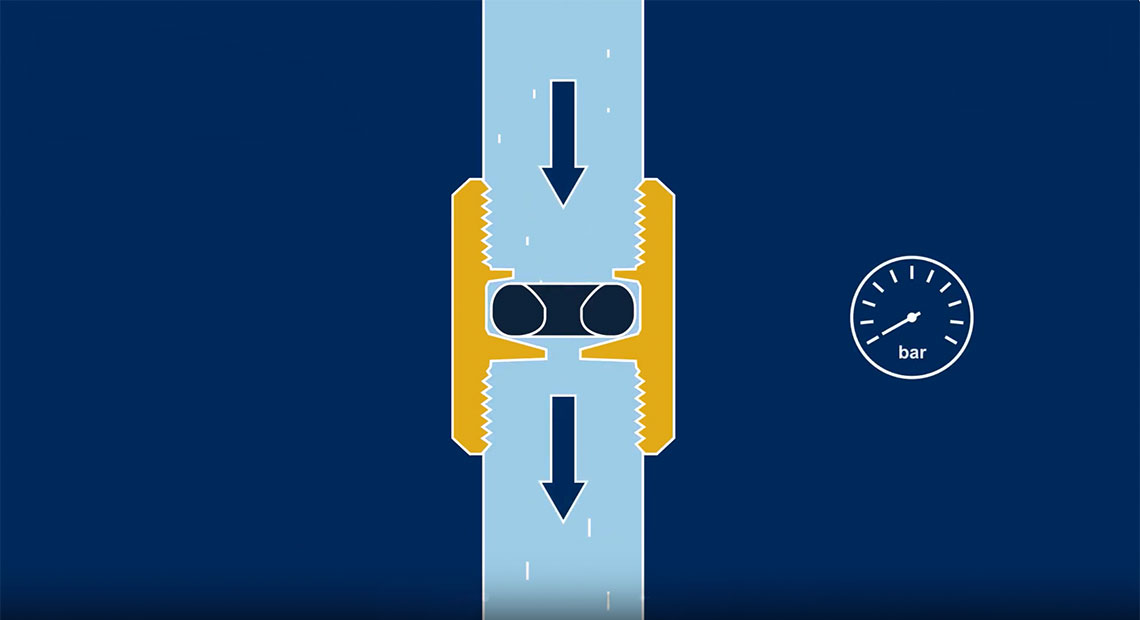

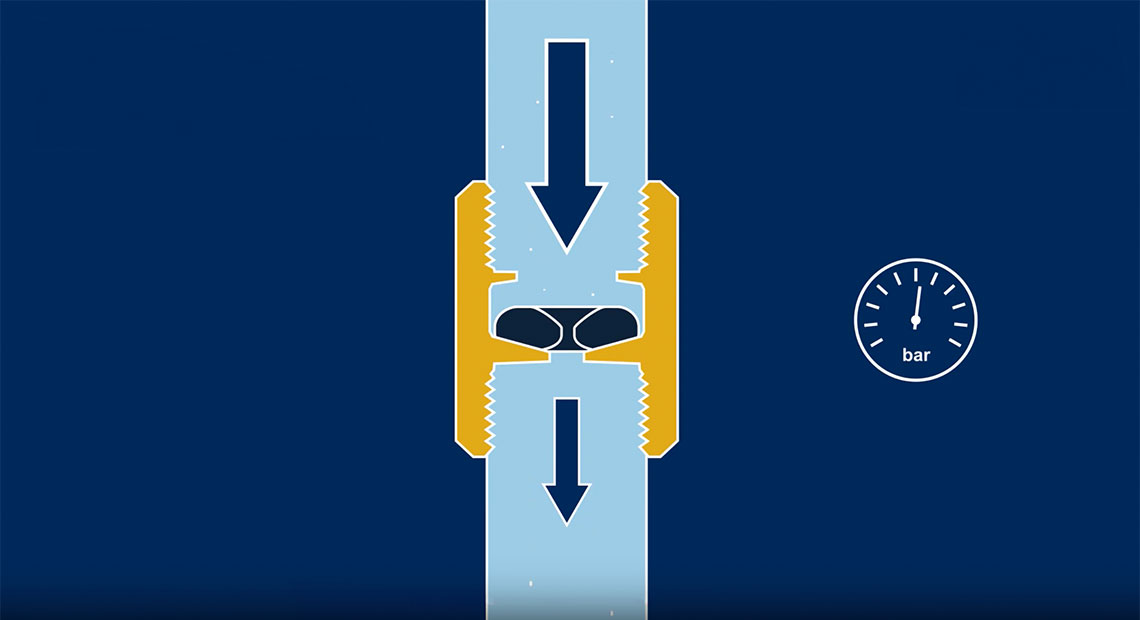

– is designed to provide a consistent, limited flow rate for water.

The BT-Maric flow limiters (commonly called constant flow valves, but also often called flow regulation valves or flow control valves) keep water flow at a specified, pre-set rate, regardless of pressure changes. These robust flow limiters offer a mechanical solution for reliable water management and equipment protection.

Bertfelt is the leading manufacturer of BT-Maric flow limiters for industrial applications.