It is important that our customers understand how our products work.

We are happy to answer your questions, but to make our service easier for you, we have compiled the answers to the most frequently asked questions in our FAQ.

Please contact us for further support if you can not find the answers that you need.

Our most frequently asked questions

Functionality of BT-Maric constant flow valves:

The BT-Maric flow control valve is designed to deliver a pre-determined constant flow rate of water and similar media regardless of pressure variations within a certain pressure range. The pressure range depends on the type of valve used.

The BT-Maric constant flow valve has an effect on the pressure, but is not designed to control the pressure in your system.

The control flow valve has no external actuation and is not adjustable after installation.

BT-Maric constant flow valves do not work with gas or air.

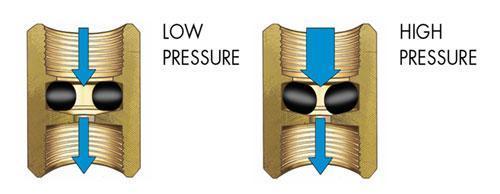

BT-Maric constant flow valves utilize a flexible rubber control O-ring with an orifice diameter that responds instantly to fluctuations of the pressure exerted. When the pressure increases the o-ring is pressed down in the conical seat and the orifice of the o-ring decreases in size in such a way that the flow remains constant at the pre-set nominal rate, and vice versa. In this way, the pre-set nominal flow rate is always kept constant regardless of the pressure variations.

BT-Maric constant flow valves will help you:

- to reduce investment and operating flow-related costs by always providing the chosen specified flow rate regardless of the pressure variations. Pressure variations often occur in systems with many points of consumption.

- to improve the water flow or similar media in your process or product by always providing the chosen specified flow rate regardless of the pressure variations. Your system will thus have a stable, constant flow rate if the pressure drop is within specified limits. It will prevent the break down or damage of equipment. It will extend life span of your equipment. It will provide valuable protection for flow rate sensitive pumps, filters, pump glands, and water distribution systems.

- to save water by limiting the flow rate at usage points. Water is a vital natural resource and needs to be saved at all times.

No, only for water and similar liquids.

An insert is the most cost-efficient solution to incorporate the constant flow function in your process or equipment for flow rates up to 233 l/min. The insert is fitted in a suitable place in your existing pipe.

It depends where the valves are located. If our constant flow valves are placed in the secondary system, it can be used in food application as category 4 (when not in direct or insignificant contact with food). Please check EC regulation 1935/2004.

The flow rate must be decided before ordering. Of course, you could always change an existing constant flow valve with one equipped with another flow rate.

Pressure Drop “or headloss”, across the valve, is simply the difference between inlet and outlet pressure, and is determined by your installation.

Yes, it is important because the constant flow function is only ensured when the pressure drop is within the specified limits. Please consult the section “about headloss” of our catalogue p.8.

We do not advise what the pressure differential will be. But it should be possible for you to calculate it if you have relevant installation data available. You will then be able to select a valve with the appropriate pressure differential range for your application. The pressure drop across the valve will in fact be determined by the parameters of each installation as it has its own individual specifications. If you are unsure if a BT-Maric valve will be suitable for your application, it will be necessary to predict what the pressure differential will be across the valve by calculating as described in page 9 of our catalogue.

The differential across the constant flow valve, will be the difference in pressure between the inlet and outlet. You can check our catalogue “calculating pressure drop”.

up to 20 years.

You can find the dimensions and weights of our constant flow valves in our catalogue.

PURCHASE OF BT-MARIC CONSTANT FLOW VALVES

Send an enquiry to one of the following addresses:

- Scandinavia, the Baltics, Poland, Italy and the rest of Europe excluding UK and Ireland: btinfo@bertfelt.com

- Netherlands, Belgium and Luxembourg: nederland@bertfelt.com

- France, Spain, Portugal and all French speaking companies: france@bertfelt.com, spain@bertfelt.com

- Germany, Austria and Switzerland (German speaking): btinfo@bertfelt.de

Our sales team will be more than happy to assist you.

You should send your price enquiry to one of the following addresses:

- Scandinavia, the Baltics, Poland, Italy and the rest of Europe excluding UK and Ireland: btinfo@bertfelt.com

- Netherlands, Belgium and Luxembourg: nederland@bertfelt.com

- France, Spain, Portugal and all French speaking companies: france@bertfelt.com, spain@bertfelt.com

- Germany, Austria and Switzerland (German speaking): btinfo@bertfelt.de

Our sales team will be more than happy to assist you.

Yes. You can.

No, as we are only dealing with B2B buyers.

You should send your enquiry to one of the following addresses:

- Scandinavia, the Baltics, Poland, Italy and the rest of Europe excluding UK and Ireland: btinfo@bertfelt.com

- Netherlands, Belgium and Luxembourg: nederland@bertfelt.com

- France, Spain, Portugal and all French speaking companies: france@bertfelt.com, spain@bertfelt.com

- Germany, Austria and Switzerland (German speaking): btinfo@bertfelt.de

It varies depending on the type of constant flow valve that you need. If we have the needed item in stock, we ship within one or two days. If we are out of stock, delivery might take 2-4 weeks. When ordering, please let us know immediately just how urgent your delivery is. We will do our best to shorten delivery time.

Our constant flow valves have a guarantee of 1 year, as already mentioned life expectancy is up to 20 years.

Yes. Just get in touch with us and we shall discuss details. You will find our contact info here.

INSTALLATION OF BT-MARIC CONSTANT FLOW VALVES

Insert must be installed the right way around or immediate failure may result. The visible part of the control rubber should meet the flow. The insert should be placed in the existing pipe works of your equipment.

Valves must be installed the right way around or immediate valve failure may result. The flow direction is indicated by an arrow stamped on the body valve.

It is recommended to orientate the valves stamped data toward the top or in such a position to facilitate identification. Bends or elbows immediately in front of valve will not affect the valves performance, however due to the velocity of the water jets exiting the valves, it is recommended that a straight pipe, the length of approximately the nominal diameter of the fitting, be fitted on valves outlet.

You can get a tighter seal by using thread tape. The maximum recommended tightness is hand tight plus a quarter turn. DO NOT TIGHTEN IT more than a quarter turn otherwise you will damage the valve. Care needs to be exercised in handling tighter seal in connection with PVC valves.

Wafer type valves are designed for mounting between smooth flat faced pipe flanges.

MAINTENANCE OF BT-MARIC CONSTANT FLOW VALVES

No specific requirements are necessary. The BT-Maric constant flow valves are self-cleaning.

Not necessarily. Much depends on your application. Our constant flow valves have a life expectancy of up to 20 years. High media temperature, abraising particles and lime may affect accuracy over time. Also, in general it can be said that over time the control rubber O-ring gets harder, over a time period of 10 years flow accuracy may drop by 5%.

Due to the valves unique design and the lack of wearing components spare parts are not available.

CERTIFICATIONS OF BT-MARIC CONSTANT FLOW VALVES

Yes. We have potable water certificates: from Australia and France.

There is no difference. These are just different designations. They are called flow limiter, flow controllers, throttle valves, fluid control valve or mass fluid control valve.

It means that the flow of a liquid/media will be always the same inside the pipeline system regardless of changes in pressure variations within a specified pressure range.

- Control the flow rate of a water and similar media regardless of the pressure variations

- Designed for flow rates starting as low as 0.15 l/min going up to over 13 500 l/min.

- Flow rates available in incremental small steps

- 100% mechanical, fully automatic and does not require additional energy

- Uniquely precise: Our standard solution Precision has an accuracy of nominal flow rate +/- 10%, for the whole pressure drop range starting as low as 1,4 Bar up to 10 Bar.

- Simple, compact, reliable and characterized by a long operating life (up to 20 years)

- Wide range of connection types and materials are available

- High Pressure solutions managing pressure differentials up to 20 Bar

- Low Pressure solutions managing pressure differentials from 0,4 Bar

- Maintenance free: no need for spare parts

- Pre-set to avoid adjustment errors or unwanted system changes => the flow rate must be specified when ordering

- Significantly reduce investment and operating costs

- Prevent equipment break-down and extend life span of your equipment/product

- Self-regulating and self-cleaning: do not clog

- The constant flow valves are mainly for water applications and these valves are particularly suitable for use on poor water quality, because the flow controlling element is a rubber material, and flexes under normal operation. This minimizes the risk of blockage and eliminates the build-up of scale.

- Save water or other media. Reduce waste.

The answer to all these questions is: install a BT-Maric constant flow valve.

Having other questions?

Contact our experts. We’re here to help!

What is your challenge?

Are you looking for a solution in order to achieve a constant water flow rate? Take a tour on our product pages or look at similar projects as presented in our cases studies to see how we helped our customers to optimize their water flow:

Full product range Case studies