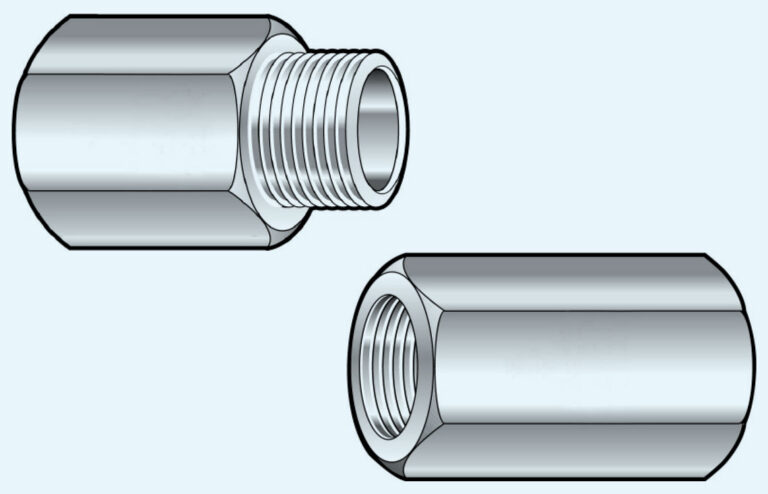

BT-Maric Threaded Constant flow valves

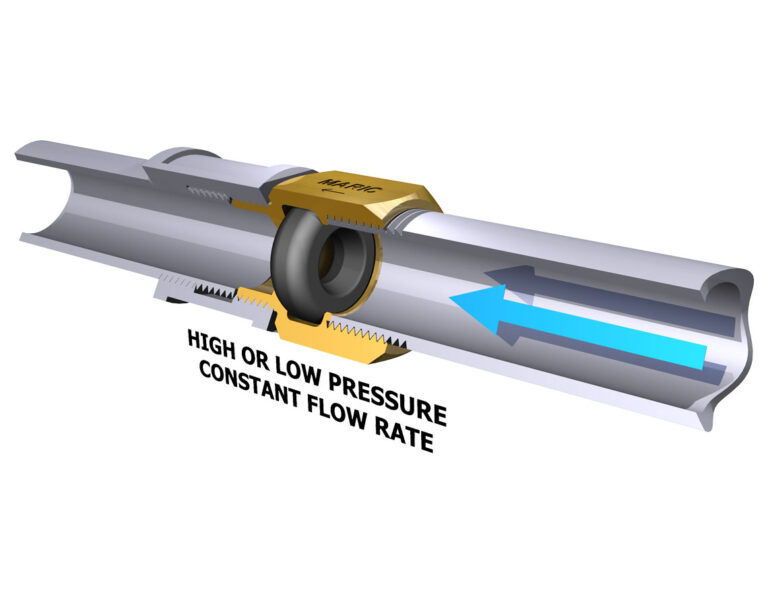

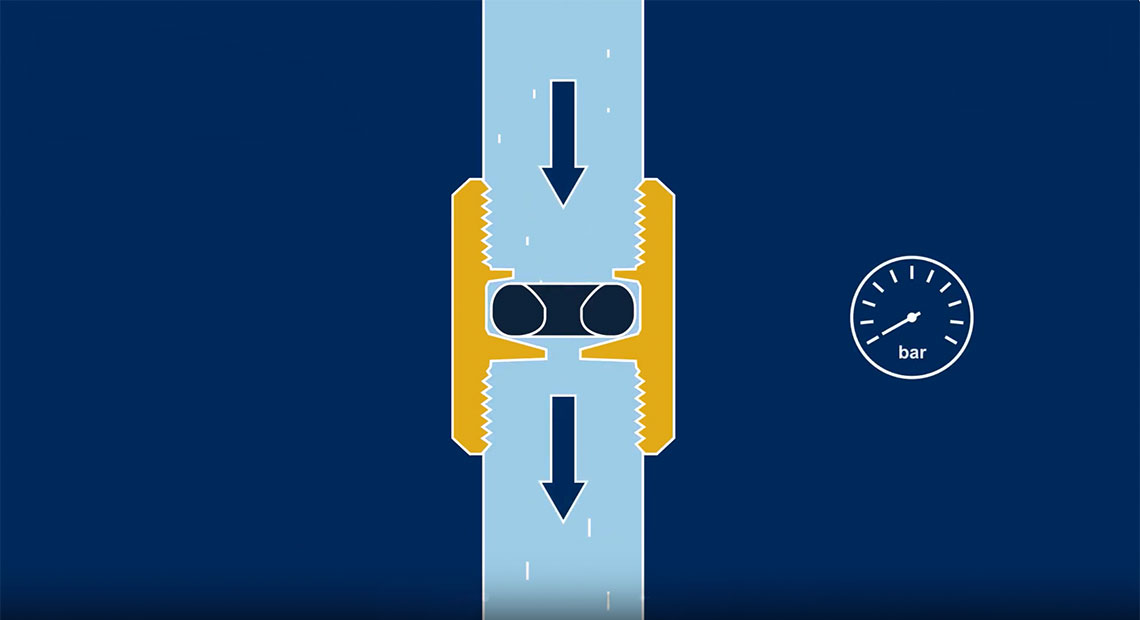

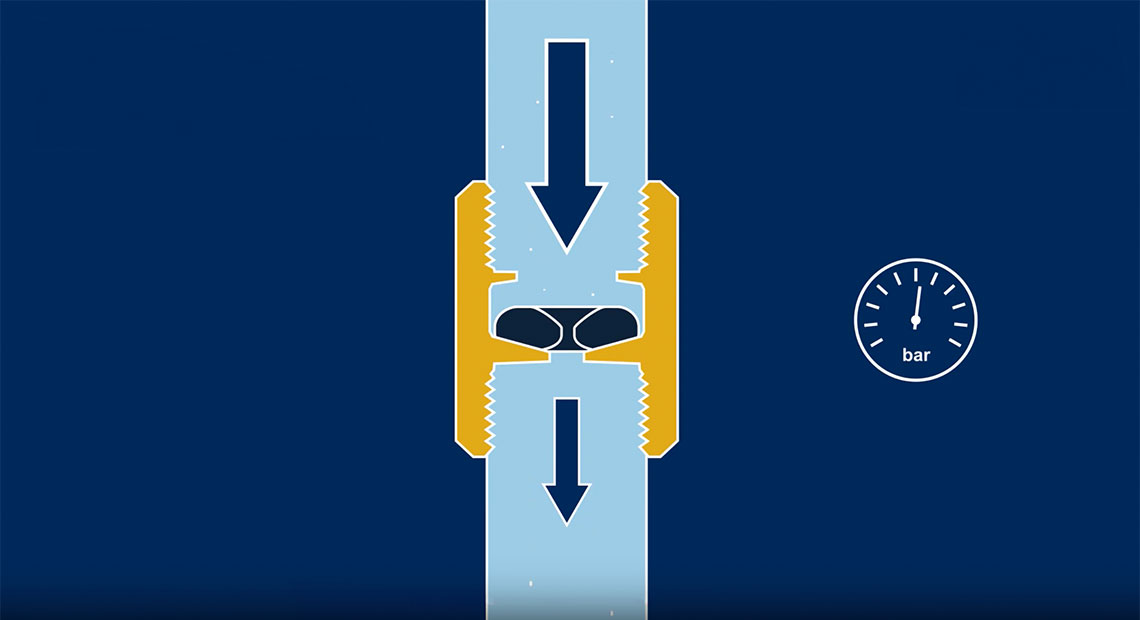

BT-Maric threaded constant flow valves are designed to deliver a constant, pre-set nominal flow rate for water and similar media—regardless of pressure fluctuations. Threaded valve bodies offer easy installation. Their mechanical design ensures reliable and accurate flow control without the need for external power or regulation systems.